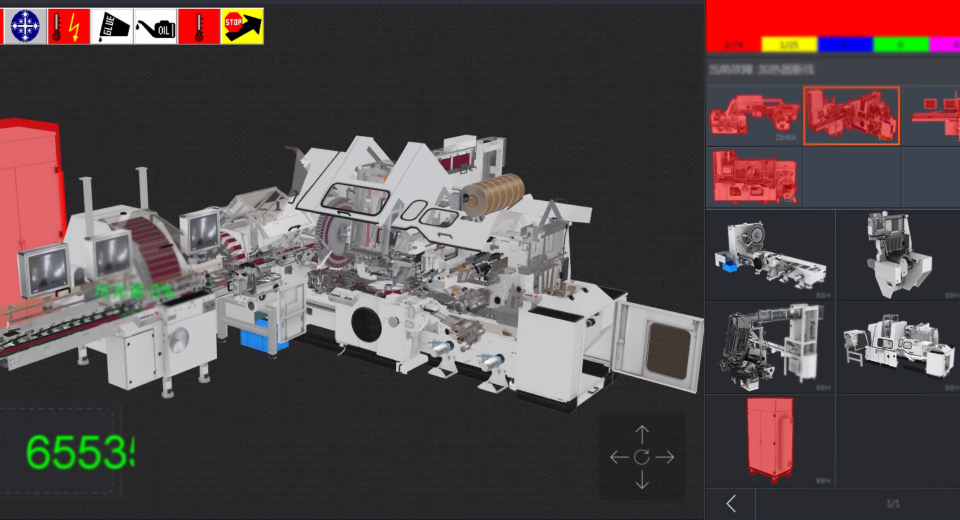

State Perception

———

Real-time perception on operating state of devices, fault alarms and other information to present the most intuitive state perception from data to graphics, and from graphics to information.

Insight into Device Information

Real-time operating condition of devices can be known, and the operation details of devices can also be presented, including the operating speed, the production schedule, the fault history, maintenance records, the early warning on spare parts wear and so on. All datum that clients are concerned about are transparently displayed, including the information of device itself and related business, so that the information of devices can be known in real time.

On-Line Diagnosis on Faults

When an alarm or a failure occurs, the position will be highlighted and the possible causes of fault will be informed. Combined with the historical fault experience, the relevant fault types can be classified, and the possible fault causes can be informed to relevant workers via different characteristics of abnormal data, to make experience related to the device into a knowledge base for online diagnosis.

Field Control

———

Devices can be controlled and operated by the way of touching screen on spot, to complete the order issuing and to realize on-site control on devices.

The Sending of Executive Order

To perform orders sent by the upper system via digital twin system for devices to assign automotic production tasks of devices.

The Uploading of Information About States

The task completion information is uploaded into the upper MES/ERP system via the digital twin system of devices to inform the completion state of production tasks in real time.

The Clearing of A Device' Faults

When the failure of a device is handled, the alarm information can be cleared via Digital Twin for Devices to update the latest state of the device in time.

The Soft Startup and Shutdown of Devices

The soft startup and shutdown of an device can be realized via digital twin of devices to avoid influences on the device due to frequent mechanical operatings.

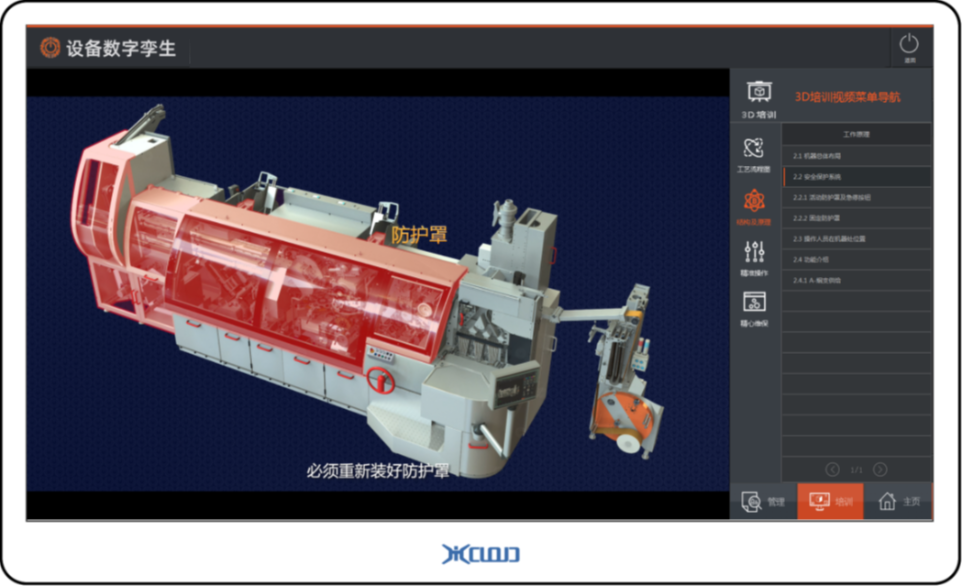

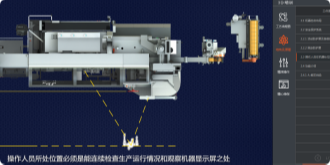

Personnel Training

———

Personnel Training

The training for new employees can be realized via Digital Twin, and device information and operating instructions can be intuitively known, so that employees can quickly get familiar with the operation of devices.

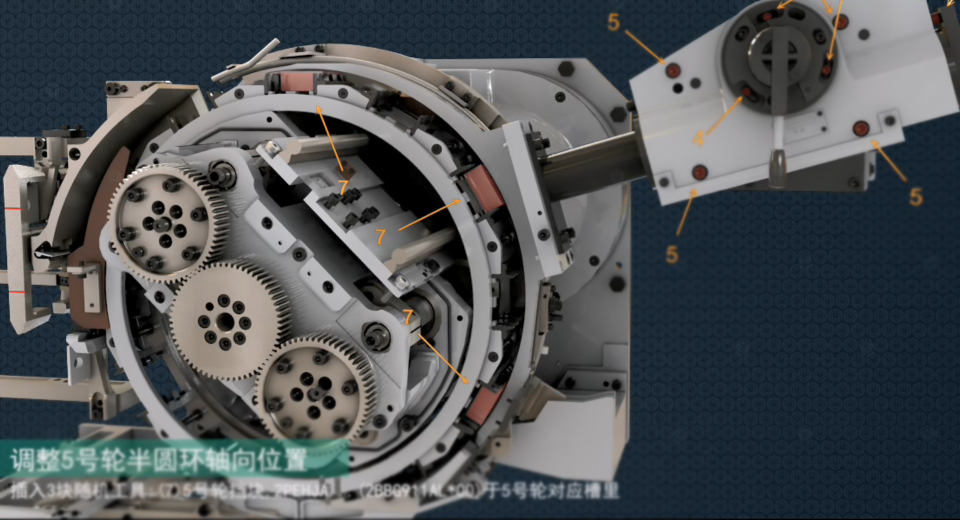

The Training of Devices

The Training for Operation Principles of Devices

The Training for Operating Devices

The Training for Fault Handling

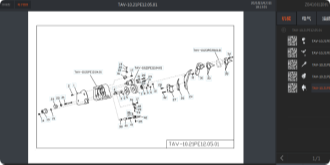

The Management of Electronic Documents

———

Able to refer to eletric documents related with devices via Digital Twin for Devices at any time, such as machine drawings, electric drawings, operating instructions, maintenance manuals.

Machine Drawings

The information vector diagrams of machine drawings can be taken out for use at any time, and can be zoomed in/out to refer to drawing information of devices and parts.

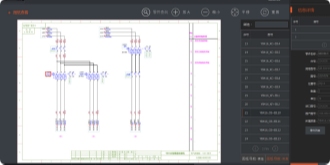

Electric Drawings

The information vector diagrams of electric drawings can be taken out for use at any time, and can be zoomed in/out to refer to drawing information of devices and parts.

Operating Instructions

To refer to related operating instructions of a device and to quickly locate contents you want to know by searching according to keywords.

Maintenence Manuals

Integrated into documents in the form of maintenance manual to realize paperless and digitalized maintenance by searching keywords of key maintenance information.

Maintenance Support

———

Maintenance Support

JIC Digital Twin Device has integrated massive bases about device maintenance experience. It can provide maintenance strategies about various kinds of breakdown scenarios, which can help maintenance workers to improve work efficiency.

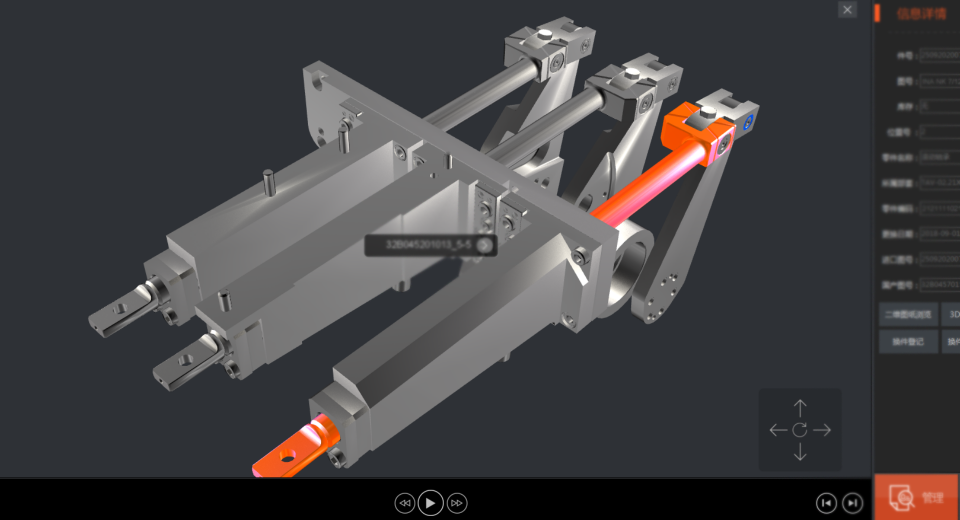

Support for Maintenance Positions

The Digital Twin for Devices can realize the positioning for specific positions or parts where there possibly occur faults according to the alarm information. According to the historical maintenance experience, the positions that need to be repaired can be classified according to different fault manifestations, and the possible situations can be analyzed according to the faults, as as to initially confirm the needed-maintenance parts and needed maintenance tools.