Clients' Actuality and Pain Points

Clients' Actuality

Shenzhen Bus Group is currently the largest enterprise to operate buses in Shenzhen, will uphold the concept of Party Construction As the Leads, People's Livehood at First, Driven By Innovation. Based on the realization of high-quality development by Ensuring Safety, Optimizing Services and Increasing Passenger Flow, it will grasp the key opportunities of Guangdong-Hong Kong-Macao Greater Bay Area, The Constructions of Pilot Demonstration Zone of Socialism with Chinese Characteristics and Regional Pilot Zone for Comprehensive Reform of State-Owned Assets and Enterpries In Shenzhen to seek long-term development via Intelligence, Standardization and Internationalization, as well as to build itself into one outstanding pilot demonstration bus enterprise with world-class influence.

Clients' Pain Points

Clients are currently faced with difficulties in digitalized transformation in the process of operation. For example, monitoring on vehicles, safe operation, maintenance for vehicles, smart decision making for operation urgently need to be improved via digitalized means.

Uncontrolled on Safety of Vehicle Operation

There occur some faults in a normal driving train due to operation devices, such as the occurence of issues about electricity facilities, signal loss and operation faults of vehicle itself.

Difficulties in Operation & Maintenance and Management of Vehicles

Operation & maintenance and management is the core part of vehicle team. Control on the operation process of vehicles is realized via the scheduling of vehicles. Therefore, the management on scheduling of vehicles is very important.

Unintuitive Operation State of Vehicles

The most intuitive phenomenon of vehicles in the fierce driving process is that the barycenter will be transferred.

Difficulties in Decision Making on Optimization of Operation

The interval mileage about various kinds of maintenance can be scientifically confirmed, which does not only keep vehicles' tech condition, but also saves costs on maintenance and repairement.

Solutions

Real-Time Monitoring on Vehicles

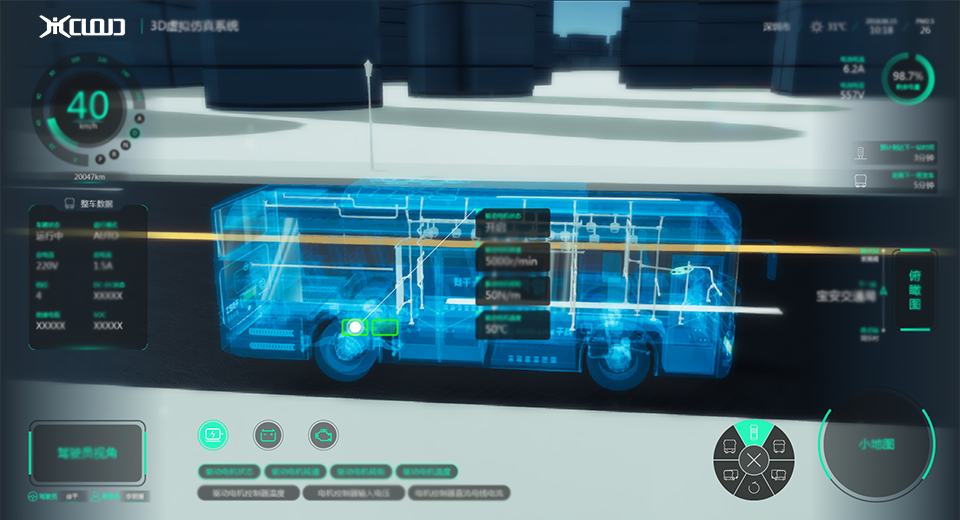

Digital Twinnig can present various datum in the driving process of every vehicle, such as accelerator, brake, driving direction, GPS positioning, bearing temperature, which can be collected to send back to the control center of vehicles to realize the intuitive monitoring on vehicles.

Alarming on the Safety of Vehicles

Via the JIC Digital Twin platform, abnormal indicators can be found according to the real-time data of vehicles and timely safety warning is sent out. Especially when it is involved in the parameters about safety of vehicles, such as high-temperature battery cell, overworn brake pad, and related workers can be reminded to strengthen control or take corresponding measures.

Smart Maintenance of Vehicles

The faults of vehicles and the possible reasons can be diagnosed via JIC Digital Twin platform. The related maintenance workers can be informed of the addresses of fault vehicles, possible fault reasons, and the needed tools. System will assign the nearest maintenance workers to ensure maintenance efficiency.

Optimization on Decision Making for Operation

According to operation data of vehicles, the analysis on operation optimization can be made. Management centers of buses have a better control of these technical details. For example, whether it is reasonable for drivers to step on accelerators and to brake; whether drivers open the doors when buses arrive at the stations; whether vehicles decelerate around the corner. These datum can be taken as the assessment indicators of drivers to regulate drivers' driving behaviors and to accelerate the optimization of business operation.

Efficiency Improvement

Management efficiency raised by 15%

The time of operation and maintenance reduced by 30%

Assets ultilization rate raised by 20%